Welcome to the Miller Bobcat 250 Parts Manual, your essential guide for understanding and maintaining your welding equipment. This manual provides detailed diagrams, part numbers, and repair instructions to ensure optimal performance and longevity of your Miller Bobcat 250 welder. Designed for both professionals and DIY enthusiasts, it serves as a comprehensive resource for troubleshooting, maintenance, and upgrades. Use this manual to master your equipment and keep it in peak condition for years to come.

1.1 Overview of the Miller Bobcat 250 Welder

The Miller Bobcat 250 is a versatile and reliable welder designed for heavy-duty applications. Known for its portability and durability, it supports MIG, TIG, and Stick welding processes, making it ideal for professionals and hobbyists alike. Engineered with advanced technology, the Bobcat 250 delivers consistent performance across various industries, including automotive, construction, and fabrication. This welder is built to withstand demanding environments while maintaining precision and efficiency, ensuring high-quality results for every project.

1.2 Importance of the Parts Manual for Maintenance

The Miller Bobcat 250 Parts Manual is indispensable for proper maintenance and repairs. It provides detailed diagrams, part numbers, and instructions, ensuring you can identify and replace components accurately. Regular maintenance extends the welder’s lifespan and prevents costly repairs. The manual serves as a vital resource for troubleshooting and keeping your equipment in optimal condition, whether you’re a professional or a DIY enthusiast. It ensures safety, efficiency, and peak performance.

1.3 How to Use the Manual Effectively

Start by familiarizing yourself with the manual’s layout, including diagrams and part listings. Use the index to quickly locate specific sections or components. Always reference part numbers when ordering replacements to ensure accuracy. Follow step-by-step instructions for maintenance and repairs, and review safety guidelines before starting any work. Regularly update your knowledge of the manual to stay informed about new procedures or updates, ensuring safe and efficient use of your Miller Bobcat 250 welder.

Safety Precautions and Guidelines

Always wear protective gear when operating the Miller Bobcat 250. Ensure proper ventilation to avoid fume inhalation. Follow manual instructions for safe equipment handling and maintenance procedures.

2.1 General Safety Tips for Handling Welding Equipment

Always wear protective gear, including gloves, safety glasses, and a welding helmet. Ensure proper ventilation to prevent inhaling fumes. Keep loose clothing tied back and avoid jewelry. Inspect equipment regularly for damage. Never touch electrical components with wet hands. Maintain a clean, clutter-free workspace. Follow the manual’s guidelines for setup and operation. Be aware of your surroundings to prevent accidents. Properly store flammable materials and keep a fire extinguisher nearby. Adhere to all safety protocols to ensure safe and efficient welding operations.

2.2 Safety Features of the Miller Bobcat 250

The Miller Bobcat 250 is equipped with multiple safety features to protect users. It includes thermal overload protection, which shuts down the unit if it overheats. The welding machine also has an automatic shut-off feature for the torch, reducing the risk of accidental starts. Additionally, the unit is designed with insulated components and a robust casing to prevent electrical shocks. Regular maintenance, as outlined in the manual, ensures these safety features remain effective, providing a secure welding environment for operators.

2.3 Precautions Before Starting Maintenance or Repairs

Before performing any maintenance or repairs, ensure the Miller Bobcat 250 is turned off and disconnected from the power source. Allow the machine to cool down to avoid burns. Use proper tools and wear protective gear, including gloves and safety glasses. Refer to the manual for specific instructions to prevent damage to components. Never attempt repairs without proper training or knowledge of the equipment. Always work in a well-ventilated, clean environment to ensure safety and accuracy during the process;

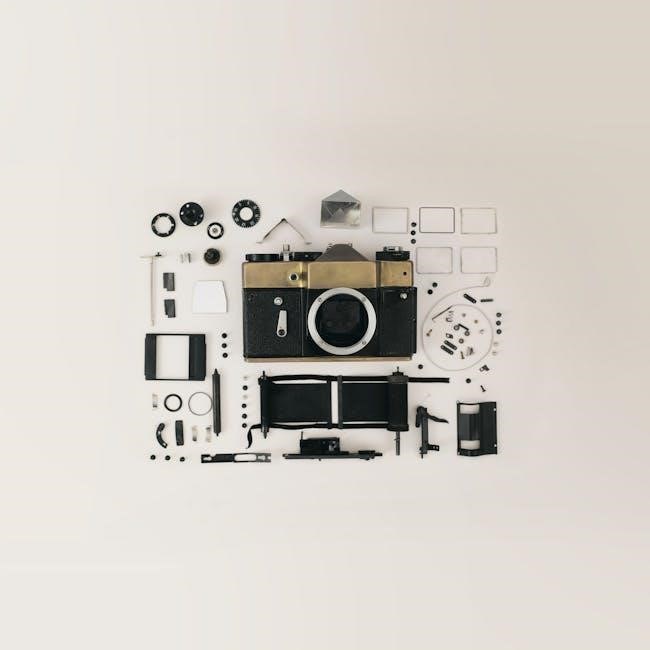

Parts Identification and Diagrams

The Miller Bobcat 250 Parts Manual includes detailed diagrams and descriptions to help identify components. These visuals simplify locating parts, ensuring accurate maintenance and repairs. Understanding the layout is crucial for effective use of the manual and proper equipment upkeep.

3.1 Understanding the Parts Diagram Layout

Welcome to the Miller Bobcat 250 Parts Manual. This section explains the layout of the parts diagrams, which are essential for identifying components. Each diagram is carefully organized to provide a clear visual representation of the welder’s structure. Key features include exploded views, numbered parts, and labels for assembly groups. Understanding this layout is crucial for accurate identification and location of components, ensuring efficient maintenance and repairs. Use the diagrams to familiarize yourself with the equipment’s anatomy and streamline your workflow.

3.2 Key Components of the Miller Bobcat 250

The Miller Bobcat 250 is composed of several critical components essential for its operation. These include the power source, welding torch, wire feeder, control panel, cooling system, and frame/chassis. Each part plays a vital role in ensuring smooth welding performance. The power source provides the necessary energy, while the welding torch delivers the arc. The wire feeder manages the welding wire, and the control panel allows for precise settings adjustment. The cooling system prevents overheating, and the durable frame ensures stability. Understanding these components is key to effective maintenance and repairs.

3.3 How to Locate Specific Parts in the Manual

The Miller Bobcat 250 Parts Manual is organized to help you quickly locate specific parts. Use the table of contents or index to navigate efficiently. For digital versions, utilize the search function to find part numbers or descriptions instantly. Each component is listed with clear diagrams and part numbers, making identification straightforward. Cross-referencing ensures accuracy, allowing you to locate and order genuine Miller parts effortlessly. This system streamlines maintenance, repairs, and upgrades, keeping your Bobcat 250 in optimal condition.

Maintenance and Service Schedule

Regular maintenance is crucial for the longevity and performance of your Miller Bobcat 250. This section outlines the recommended service intervals and procedures to ensure optimal functionality. By following the schedule, you can prevent wear and tear, reduce downtime, and extend the life of your equipment. Proper upkeep also enhances safety and welding quality, making it essential for both professional and personal use. Refer to the manual for detailed guidelines tailored to your welder’s needs.

4.1 Recommended Maintenance Intervals

Regular maintenance ensures the Miller Bobcat 250 operates efficiently and safely. Daily checks include inspecting the welder’s exterior, cleaning dust, and verifying all connections. Weekly, examine the cooling system, air filters, and wiring for wear or damage. Monthly, lubricate moving parts, test the arc performance, and check gas lines for leaks. Every 500 hours, replace the spark plug and inspect the welder’s internal components. Adhering to these intervals prevents downtime and extends equipment life, ensuring reliable performance for all welding tasks.

4.2 Step-by-Step Maintenance Procedures

Start by powering off and cooling the welder. Clean the exterior and internal components using compressed air. Inspect the welding gun, cable, and connections for wear. Replace the spark plug and check the gas line for leaks. Lubricate moving parts and ensure proper ventilation. Refer to the parts manual for specific torque values and replacement guidelines. Always follow safety protocols and document maintenance for future reference to ensure the equipment remains in optimal condition.

4.3 Tools and Equipment Required for Maintenance

Maintenance requires basic tools like wrenches, screwdrivers, and pliers. A multimeter is essential for electrical checks, while compressed air helps clean internal components. Safety gear, including gloves and goggles, is crucial. A torque wrench ensures proper bolt tightening, and a wire brush aids in cleaning corrosion. Refer to the manual for specific tools needed for your Miller Bobcat 250. Having these tools readily available ensures efficient and safe maintenance procedures.

Troubleshooting Common Issues

This section identifies frequent problems with the Miller Bobcat 250, such as power issues or faulty parts, and guides you through diagnosis and effective solutions using the manual.

5.1 Identifying Common Problems with the Miller Bobcat 250

Welcome to the troubleshooting section of the Miller Bobcat 250 Parts Manual. This guide helps identify common issues such as power fluctuations, faulty wiring, or malfunctioning components. Users often report problems like inconsistent welding performance, overheating, or failed ignition systems. The manual provides detailed diagnostic steps and part identification to address these issues effectively. By referencing the diagrams and repair instructions, you can pinpoint and resolve problems efficiently, ensuring your welder operates at peak performance.

5.2 Diagnostic Techniques Using the Parts Manual

Greetings! The Miller Bobcat 250 Parts Manual provides visual guides and step-by-step processes to diagnose issues efficiently. Use the detailed diagrams to identify faulty components and follow the troubleshooting checklist to pinpoint problems. The manual also includes a list of common symptoms and their corresponding solutions, helping you resolve issues like inconsistent welding performance or electrical malfunctions. This section empowers you to conduct thorough diagnostics and perform effective repairs, ensuring your equipment operates smoothly and reliably.

5.3 Solutions for Frequently Encountered Issues

The Miller Bobcat 250 Parts Manual offers practical solutions for common issues, such as inconsistent weld quality or duty cycle overload. It provides repair procedures for faulty components like the wire feeder or cooling system. By referencing the manual, users can address problems systematically, ensuring reliable performance. This section is designed to help users resolve issues quickly and effectively, minimizing downtime and extending equipment longevity.

Welding and Operational Tips

Optimize welding performance by adjusting settings for specific tasks, ensuring proper wire feed speed, and maintaining clean connections. Regularly inspect and clean the gun and liner to prevent issues. Use the correct shielding gas and follow recommended parameters for different materials. Store the welder in a dry, cool place to extend its lifespan and reliability.

6.1 Optimizing Welding Performance

Enhance welding efficiency by ensuring proper machine setup and maintenance. Clean the welding gun and cable regularly to maintain optimal conductivity. Adjust voltage and wire feed speed according to material thickness and type. Use the correct polarity for your electrode to achieve better arc stability. Maintain a consistent travel speed to avoid overheating or lack of penetration. Refer to the parts manual for specific settings and maintenance tips to maximize performance and longevity of the Miller Bobcat 250 welder.

6.2 Adjusting Settings for Different Welding Tasks

Adjust voltage based on material thickness and type for optimal arc performance. Fine-tune wire feed speed to achieve precise control over weld bead size and penetration. Select the correct polarity setting for your electrode to ensure proper arc characteristics. Refer to the parts manual for specific recommendations tailored to various welding tasks and materials. Proper adjustments enhance weld quality and equipment longevity.

6.3 Best Practices for Extending Equipment Life

Regularly clean the wire feeder and torch to prevent debris buildup. Store the welder in a dry, cool environment to avoid rust and moisture damage. Lubricate moving parts as specified in the manual to ensure smooth operation. Follow the maintenance schedule to replace worn components promptly. Use genuine Miller parts for compatibility and longevity. Avoid exposing the unit to extreme temperatures or overloading it beyond its rated capacity.

Parts Replacement and Upgrades

Use genuine Miller parts for replacements to ensure compatibility and performance. Follow torque specifications and installation guidelines in the manual for proper upgrades and replacements.

7;1 When to Replace Parts

Replace parts when they show signs of wear, such as cracks, rust, or reduced performance. The manual highlights critical components requiring regular inspection, like the welder’s contact tips and shielding gas nozzles. Replace consumables when they no longer ensure proper shielding or clean welds. Follow the recommended maintenance schedule to prevent unexpected equipment failure. Addressing wear early extends the welder’s lifespan and maintains optimal performance;

7.2 How to Order Genuine Miller Parts

To order genuine Miller parts, visit the official Miller website or contact authorized dealers. Use the part numbers listed in the manual to ensure accuracy. For convenience, utilize Miller’s online parts portal, which allows quick searches and direct purchases. Always verify the seller’s authenticity to avoid counterfeit items. Contact Miller customer support for assistance with orders or inquiries about specific components.

7.3 Upgrading Components for Enhanced Performance

Upgrading components can enhance the Miller Bobcat 250’s performance. Consult the parts manual to identify compatible upgrades, such as high-performance welding torches or advanced cooling systems. Ensure all upgrades are genuine Miller parts for optimal compatibility. Contact authorized dealers for recommendations and purchase. Avoid non-genuine parts to maintain warranty and safety standards. Always follow installation guidelines or consult a certified technician for complex upgrades.

Technical Specifications

The Miller Bobcat 250 operates at 250 amps with a 100% duty cycle at 240V. It weighs 475 lbs and measures 28.5″ x 18.5″ x 34.5″.

8.1 Power and Performance Ratings

The Miller Bobcat 250 delivers 250 amps of welding power at 100% duty cycle for continuous operation. It operates on 240V input, providing consistent arc performance for MIG, TIG, and Stick welding. The machine is designed for versatility, handling various welding processes efficiently. Its power rating ensures robust performance in demanding environments, making it suitable for industrial and heavy-duty applications. The welder’s specifications highlight its durability and reliability for professional use.

8.2 Dimensions and Weight of the Miller Bobcat 250

The Miller Bobcat 250 measures approximately 28.5 inches in height, 18.5 inches in width, and 34 inches in length. It weighs around 580 pounds, making it portable yet robust for industrial use. Its compact design allows easy transportation to job sites while maintaining durability. The dimensions and weight are optimized for balance between portability and stability, ensuring reliable performance in various welding environments.

8.3 Compliance with Safety Standards

The Miller Bobcat 250 adheres to rigorous safety standards, ensuring operator protection and reliable performance. It meets CSA, UL, and OSHA requirements, guaranteeing compliance with industry safety protocols. The welder is designed to withstand harsh environments while maintaining safety certifications. Users can rely on its compliance with international standards, ensuring safe operation across various applications. The manual provides detailed information on safety features and compliance, aiding in proper usage and adherence to regulations.

Warranty and Support Information

The Miller Bobcat 250 is backed by comprehensive warranty programs and dedicated customer support. Access to online resources and expert assistance ensures optimal equipment performance and longevity.

9.1 Understanding the Warranty Coverage

The Miller Bobcat 250 parts manual outlines the warranty coverage, ensuring protection against defects in materials and workmanship. The standard warranty typically includes a 3-year coverage for parts and labor, with specific conditions for registration and maintenance. Extended warranties may also be available for certain components, providing additional peace of mind. Always refer to the manual for detailed terms and conditions to ensure compliance and maximize warranty benefits effectively.

9.2 Contacting Miller Customer Support

Miller Electric offers multiple ways to contact their customer support for inquiries about the Bobcat 250. You can reach them via phone at [Phone Number], through email at [Email Address], or by visiting their official website. Their support team is available [insert hours of operation]. For faster service, have your equipment’s serial number ready. Regional contact information is also available on their website to ensure you receive prompt assistance.

9.3 Accessing Additional Resources

Beyond the parts manual, Miller Electric offers various resources to support your Bobcat 250. Visit their official website for instructional videos, FAQs, and troubleshooting guides. Online forums and community discussions can also provide insights from experienced users. Additionally, Miller’s resource library includes technical bulletins and maintenance tips to help you maximize your welder’s performance and longevity. These resources are easily accessible online, ensuring you have comprehensive support whenever needed.

Downloading the Miller Bobcat 250 Parts Manual

Visit Miller’s official website, navigate to the support section, and select the Bobcat 250 model. Download the PDF manual directly from trusted sources to ensure authenticity and accessibility for easy reference.

10.1 Official Sources for the PDF Manual

The Miller Bobcat 250 parts manual PDF is available on Miller’s official website under the support or resources section. Visit MillerWelds.com and navigate to the product page for the Bobcat 250. Additionally, authorized Miller distributors and partner websites may provide direct download links. Ensure you download from trusted sources to avoid unauthorized or outdated versions. Always verify the manual’s authenticity by cross-referencing with Miller’s official documentation.

10.2 Verifying the Authenticity of the Manual

To ensure the Miller Bobcat 250 parts manual PDF is genuine, verify the publisher is Miller Electric Mfg. LLC. Check for official branding, such as logos and trademarks. Compare the content with the official website or contact Miller customer support for confirmation. Authentic manuals will have consistent formatting, accurate technical details, and proper copyright information. Be cautious of third-party sources that may alter or misrepresent the content.

10.3 Tips for Navigating the Digital Manual

To effectively navigate the Miller Bobcat 250 parts manual PDF, utilize bookmarks for quick section access. Use the search function to find specific parts or terms instantly. Zoom in on detailed diagrams for clarity. Familiarize yourself with the table of contents and index for easy navigation. Regularly check for updates to ensure you have the latest version. Leveraging these features enhances your user experience and maintenance efficiency.