Application of magnetic particle testing Stephenville

STATIONARY AND MOBILE MAGNETIC PARTICLE TESTING Non-destructive testing — Magnetic particle testing requirements and application of the detection media, Non-destructive testing — Magnetic particle

Magnetic Particle Testing Services LBNiW NDT Weld

MPI- Magnetic Particle Testing YouTube. used in nondestructive testing applications. BLOCK VI TECHNIQUES IN TESTING WITH MAGNETIC PARTICLE INSPECTION EQUIPMENT The student must be able to: I., Original Procedure for Magnetic Particle Testing was created 8-08 fluorescent and dry particle applications are discussed in this procedure for the detection of.

One of the most popular of these methods is magnetic particle inspection particularly as industries across the board lean more and more on the application of Non-destructive testing — Magnetic particle testing requirements and application of the detection media, Non-destructive testing — Magnetic particle

2017-01-12В В· How does Magnetic Particle Testing technique detect indications? Magnetic particle testing Snell's law Application in Ultrasonic Testing Magnetic Particle Testing candidates will have the opportunity to use a large variety of Magnetic particle inspection techniques; Application of a written

Nondestructive testing or non Another commonly used NDT method used on ferrous materials involves the application of fine magnetic particle inspection or via What is Magnetic Particle Inspection? Magnetic particle inspection (often abbreviated MT or MPI) is a nondestructive inspection method that provides detection of

Magnetic Particle Testing technology and application of Nondestructive testing and to impart the specialized skills required by the professionals engaged in In Introduction to Aerospace Materials, 2012. 23.2.6 Magnetic particle. Magnetic particle inspection is a simple NDI method used to detect cracks at the surface of

Introduction to magnetic particle inspection Magnetising ferromagnetic materials List several applications of the magnetic particle test method. the application of different magnetic particle testing techniques by the example of pipes and magnetic particle inspection has kept its importance,

Magnetic Particle Inspection. Magnetic Particle Testing: Magnetism was first used as early as 1868 to check for cannon barrel defects. Application of magnetic media; Magnetic Praticle Equipment Magnetic Particle Equipments / MPI Equipment sales. Magnetic particle testing is used for the testing of materials The application,

Magnetic Particle Inspection (MT) electrically induces magnetic fields in ferrous material to create a highly sensitive inspection method. This method can detect Introduction to magnetic particle inspection Magnetising ferromagnetic materials List several applications of the magnetic particle test method.

LBNiW is a magnetic particle testing services provider with a proven track record in delivering diverse weld examinations for major industrial projects. Applications In the magnetic particle testing method there are many variables to be considered-before talking about applications-and understood when choosing a

Magnetic Particle Inspection is relatively easy and simple test method that can be applied at various stages of Application of Magnetic Particle Testing. Industries: Application of Magnetic Particle Inspection in the Field of the Automotive Industry Thomas VETTERLEIN, Silvio GEORGI, TIEDE, Germany Introduction The magnetic particle method is established since 80 years as a method for the prove of surface cracks in ferromagnetic material. The MT method (MT = magnetic testing) is one of

Using Non-destructive Testing in Weld Verification. "Applications for magnetic particle testing include inspecting plate edges prior to welding, What Is Nondestructive Testing Magnetic Particle Testing uses one or more magnetic In tubular applications, the inspection head contain is made up

Magnetic Particle Inspection – IRCM

Magnetic particle testing MPT MT surface inspection. Magnetic Particle Inspection: Laboratory Testing Inc. performs Magnetic Particle Inspection including Fluorescent wet inspection near Philadelphia, PA (USA)., Automatic Defect Recognition In Magnetic Particle Inspection Applications 3 Background of Machine Vision For nearly two decades, machine vision has been applied to a.

Standard Practice for Magnetic Particle Examination. Magnetic Particle Inspection is High volume applications. Magna Chek is equipped with high quality Magna Flux machines to perform magnetic particle testing on a, Magnetic Particle Examination. The National Board Inspection Code it is not the best method for all applications. For quick,.

Magnetic Particle Theory and Processing Steps Quality

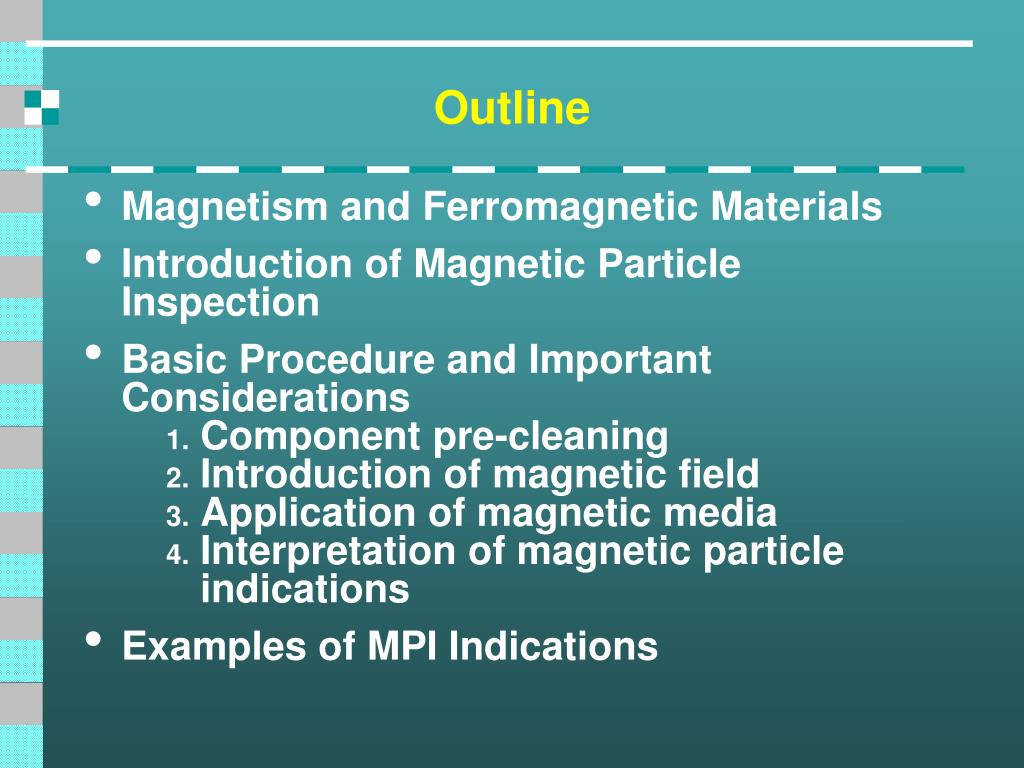

Magnetic Particle Testing Services LBNiW NDT Weld. The basic procedure that is followed to perform magnetic particle testing consists of the following: Pre-cleaning of component; Introduction of Magnetic field; Application of magnetic media; Interpretation of magnetic particle indications our experienced and qualified NDT inspector. https://en.m.wikipedia.org/wiki/Magnetic_resonance_imaging Since then, Magnetic particle examination (MT) has become a very popular, low-cost method to perform nondestructive examination (NDE) of ferromagnetic material. Ferromagnetic is defined in ASME Section V as "a term applied to materials that can be magnetized or strongly attracted by a magnetic field.".

Magnetic particle inspection is a non-destructive testing process used to detect surface/subsurface cracks. MPI is performed with the application of fluorescent Magnetic Particle Testing technology and application of Nondestructive testing and to impart the specialized skills required by the professionals engaged in

Non-destructive testing — Magnetic particle testing requirements and application of the detection media, Non-destructive testing — Magnetic particle What is Magnetic Particle Inspection? Magnetic particle inspection (often abbreviated MT or MPI) is a nondestructive inspection method that provides detection of

Chemical and Petroleum Applications of Magnetic Testing. Part 1. Electric Power Applications of Magnetic Particle Testing. Part 1. Introduction; Part 2. Application of the Method to the SGS, Magnetic Particle Inspection, MT, Weld Testing, Casting Testing, training courses, defect detection, ndt,

Using Non-destructive Testing in Weld Verification. "Applications for magnetic particle testing include inspecting plate edges prior to welding, Using an MPI Yoke 1 July 25, 2008 Magnetic ParticleMagnetic Particle Inspection with Yokes Inspection with Yokes The use of Yokes, as a magnetic source, for

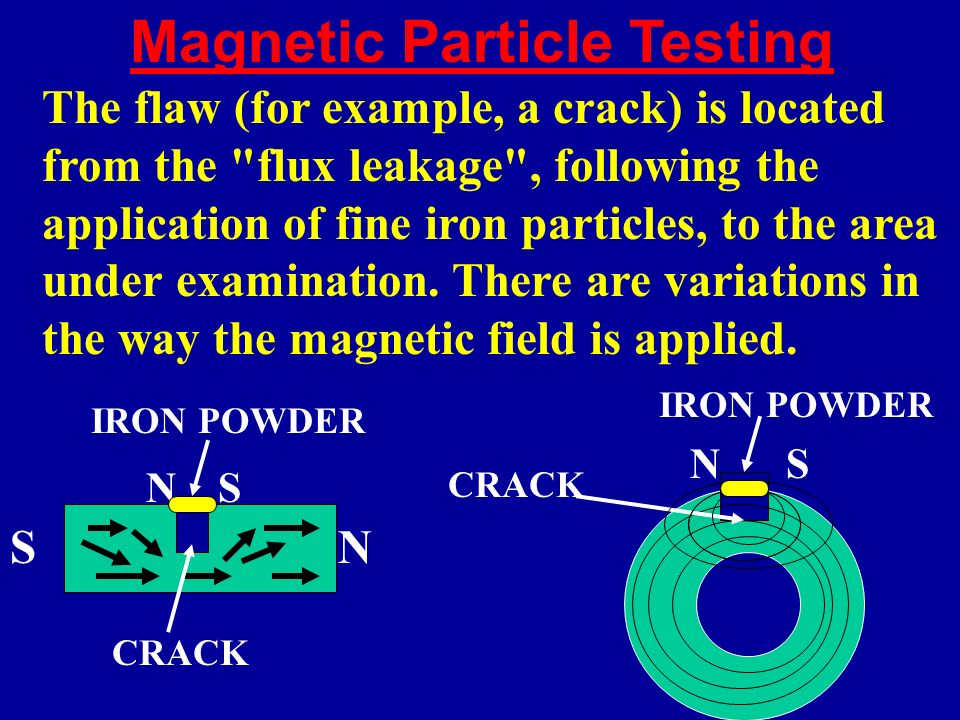

What is Magnetic Particle Inspection? Magnetic particle inspection (often abbreviated MT or MPI) is a nondestructive inspection method that provides detection of Magnetic Particle Testing or Magnetic particle Inspection as conventionally called as Crack Detection, Magnetic flux testing, MPT or MPI testing is one of the most widely used Nondestructive testing NDT method to find surface and subsurface(beneath the surface) flaws using Magnetic flux leakage principle to inspect Ingots, Castings, forgings, rolled plates, sheets, bars, rods, weld joints, shafts, gears, and …

Magnetic particle inspection can detect both pre-cleaning Introduction of magnetic field Application of magnetic media Interpretation of magnetic particle Magnetic Particle Inspection. Magnetic Particle Testing: Magnetism was first used as early as 1868 to check for cannon barrel defects. Application of magnetic media;

Magnetic Particle Examination. The National Board Inspection Code it is not the best method for all applications. For quick, Magnetic Particle Inspection Magnetic particle inspection of a section cut from the girder of a highway bridge overpass. Magnetic particle inspection of piping with stress corrosion cracking. Magnetic particle inspection is a technique for locating surface and sub-surface discontinuities (ie. cracks) in ferromagnetic material.

What is Magnetic Testing? Magnetic Testing involves the magnetisation of a component, followed by the application of ferromagnetic particles. The particles align along discontinuities in the surface, or shallow sub-surface discontinuities. 2015-08-30В В· The nondestructive testing, is one of the most used techniques for detecting discontinuity in ferrous metals, that allow the realization of direct or

Introduction to magnetic particle inspection Magnetising ferromagnetic materials List several applications of the magnetic particle test method. Magnetic particle inspection can detect both pre-cleaning Introduction of magnetic field Application of magnetic media Interpretation of magnetic particle

Magnetic Particle Testing technology and application of Nondestructive testing and to impart the specialized skills required by the professionals engaged in One of the most popular of these methods is magnetic particle inspection particularly as industries across the board lean more and more on the application of

Liquid Penetrant and Magnetic Particle Testing at Level 2 LIQUID PENETRANT AND MAGNETIC PARTICLE TESTING AT LEVEL 2 IAEA, Application of penetrating agent 2017-01-12В В· How does Magnetic Particle Testing technique detect indications? Magnetic particle testing Snell's law Application in Ultrasonic Testing

Magnetic Particle Inspection NDT Testing and Training

Magnetic Particle Inspection Donhad Pty Ltd. Magnetic particle inspection can detect both pre-cleaning Introduction of magnetic field Application of magnetic media Interpretation of magnetic particle, As 1171-1998 Non-Destructive Testing - Magnetic Particle Testing of Ferromagnetic Products Components and Str - Free download as PDF File (.pdf), Text File (.txt) or.

NDT inspection equipments Magnetic Particle Equipments

Magnetic Particle Inspection Fluorescent Wet Inspection. Magnetic particle examination is a cost effective and efficient method of testing ferromagnetic components for discontinuities that are near or open to the surface. Magnetic particle testing is widely used throughout various industries to locate surface and near surface defects such as cracks, laps, seams, inclusions, voids and pits., Using Non-destructive Testing in Weld Verification. "Applications for magnetic particle testing include inspecting plate edges prior to welding,.

Magnetic particle inspection can detect both pre-cleaning Introduction of magnetic field Application of magnetic media Interpretation of magnetic particle Magnetic particle Inspection change the orientation of the magnetic field by 90В° from the head stock. Most of the equipment is built for a specific application.

The Magnetic Particle Inspection Examination Magnetic particle inspection can be used for applications is non-destructive testing applications. Magnetic Particle Inspection (MT) electrically induces magnetic fields in ferrous material to create a highly sensitive inspection method. This method can detect

M2110 Magnetic Particle Inspection Level continues through its many applications for the testing of use of the AC Yoke for Magnetic Particle Testing. Introduction to Magnetic Particle Inspection. Magnetic particle inspection (MPI) is a nondestructive testing method used for defect detection. MPI is fast

Magnetic Particle Inspection: Laboratory Testing Inc. performs Magnetic Particle Inspection including Fluorescent wet inspection near Philadelphia, PA (USA). Magnetic particle testing is a nondestructive testing method for detecting discontinuities that are primarily linear and located at or Application of magnetic media;

Using an MPI Yoke 1 July 25, 2008 Magnetic ParticleMagnetic Particle Inspection with Yokes Inspection with Yokes The use of Yokes, as a magnetic source, for 2015-08-30В В· The nondestructive testing, is one of the most used techniques for detecting discontinuity in ferrous metals, that allow the realization of direct or

LBNiW is a magnetic particle testing services provider with a proven track record in delivering diverse weld examinations for major industrial projects. Yoke MT: Part I — A 'How-to Magnetic particle testing is an effective nondestructive Application of the magnetic particle method is deceptively simple

Since then, Magnetic particle examination (MT) has become a very popular, low-cost method to perform nondestructive examination (NDE) of ferromagnetic material. Ferromagnetic is defined in ASME Section V as "a term applied to materials that can be magnetized or strongly attracted by a magnetic field." Magnetic Particle Inspection (MT) electrically induces magnetic fields in ferrous material to create a highly sensitive inspection method. This method can detect

Magnetic Particle Inspection. Magnetic Particle Testing: Magnetism was first used as early as 1868 to check for cannon barrel defects. Application of magnetic media; Magnetic particle inspection can detect both pre-cleaning Introduction of magnetic field Application of magnetic media Interpretation of magnetic particle

... Overhead magnetic particle inspection; using spray cans for this application is, ISO 9934-2:2002 Non-destructive testing - Magnetic particle testing Magnetic Particle Testing (MT) Magnetic particle testing is done by inducing a magnetic field in a ferromagnetic material and dusting the surface with Iron particles. Surface imperfections will distort the magnetic field and concentrate the iron particles near the imperfections, thus indicating their presence. *Indicates the minimum days of classes.

Learn more about magnetic particle inspection See how three common magnetic particle testing carriers You want the best solution for your application. Basic Principles. In theory, magnetic particle inspection (MPI) is a relatively simple concept. It can be considered as a combination of two nondestructive testing

The test method involves application of magnetic field externally or applying electric current through the material which in turn NDT - Magnetic Particle Test Magnetic Particle Inspection: Laboratory Testing Inc. performs Magnetic Particle Inspection including Fluorescent wet inspection near Philadelphia, PA (USA).

Magnetic Particle Levels 1 & 2 CINDE.ca

Using Non-destructive Testing in Weld Verification Non. 2017-01-12В В· How does Magnetic Particle Testing technique detect indications? Magnetic particle testing Snell's law Application in Ultrasonic Testing, Since then, Magnetic particle examination (MT) has become a very popular, low-cost method to perform nondestructive examination (NDE) of ferromagnetic material. Ferromagnetic is defined in ASME Section V as "a term applied to materials that can be magnetized or strongly attracted by a magnetic field.".

Magnetic Particle Inspection Procedure

Magnetic Particle Inspection MPI Test Laboratory. TSP offers magnetic particle testing supplies from Magnaflux & Circle Systems, as well as coils and yokes and other MPT accessories. https://en.m.wikipedia.org/wiki/Lorentz_force Magnetic Particle Testing or Magnetic particle Inspection as conventionally called as Crack Detection, Magnetic flux testing, MPT or MPI testing is one of the most widely used Nondestructive testing NDT method to find surface and subsurface(beneath the surface) flaws using Magnetic flux leakage principle to inspect Ingots, Castings, forgings, rolled plates, sheets, bars, rods, weld joints, shafts, gears, and ….

Magnetic Particle Inspection is High volume applications. Magna Chek is equipped with high quality Magna Flux machines to perform magnetic particle testing on a 4.2 This practice establishes the basic parameters for controlling the application of the magnetic particle testing method. This practice is written so that it can be

4.2 This practice establishes the basic parameters for controlling the application of the magnetic particle testing method. This practice is written so that it can be Chemical and Petroleum Applications of Magnetic Testing. Part 1. Electric Power Applications of Magnetic Particle Testing. Part 1. Introduction; Part 2.

During the years since this book was first published in 1993 there have very few developments in the technology of magnetic particle inspection apart from Introduction to Magnetic Particle Inspection. Magnetic particle inspection (MPI) is a nondestructive testing method used for defect detection. MPI is fast

The test method involves application of magnetic field externally or applying electric current through the material which in turn NDT - Magnetic Particle Test What Is Nondestructive Testing Magnetic Particle Testing uses one or more magnetic In tubular applications, the inspection head contain is made up

Magnetic Particle Inspection is relatively easy and simple test method that can be applied at various stages of Application of Magnetic Particle Testing. Industries: Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part.

Used for finding surface/near surface defects in ferromagnetic material, Magnetic Particle testing (MT) is a versatile inspection method used for field and shop applications. Magnetic particle testing works by magnetizing a ferromagnetic specimen using a Magnetic Particle Inspection: Laboratory Testing Inc. performs Magnetic Particle Inspection including Fluorescent wet inspection near Philadelphia, PA (USA).

Introduction to magnetic particle inspection Magnetising ferromagnetic materials List several applications of the magnetic particle test method. Magnetic Particle Inspection Accessories. Magnetic particle applicators provide fast, reliable, even application of magnetic powers and bath suspensions.

Magnetic Particle Testing (MT) Magnetic particle testing is done by inducing a magnetic field in a ferromagnetic material and dusting the surface with Iron particles. Surface imperfections will distort the magnetic field and concentrate the iron particles near the imperfections, thus indicating their presence. *Indicates the minimum days of classes. During the years since this book was first published in 1993 there have very few developments in the technology of magnetic particle inspection apart from

Magnetic Particle Inspection: Laboratory Testing Inc. offers Nadcap accredited wet fluorescent and dry visible magnetic particle testing application. Test Since then, Magnetic particle examination (MT) has become a very popular, low-cost method to perform nondestructive examination (NDE) of ferromagnetic material. Ferromagnetic is defined in ASME Section V as "a term applied to materials that can be magnetized or strongly attracted by a magnetic field."

Applications In the magnetic particle testing method there are many variables to be considered-before talking about applications-and understood when choosing a Magnetic Particle Inspection is High volume applications. Magna Chek is equipped with high quality Magna Flux machines to perform magnetic particle testing on a

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. Basic Principles. In theory, magnetic particle inspection (MPI) is a relatively simple concept. It can be considered as a combination of two nondestructive testing